The Look of Rust Without Compromising Integrity

Painted Rust Finishes vs Real Rust Finishes

The oxidization of steel sees the reaction of iron and oxygen to environmental elements such as moisture, to create a reddish-brown oxide, often known as rust. While this color provides warmth and an appealing visual effect for certain designs, rust represents the degradation of the metal. This is an ongoing process and over time, can consume the metal entirely, completely compromising the metal’s structural integrity.

Naturally occurring rust on a steel surface

This finish has gained popularity in modern building design for its rustic or industrial aesthetic. However, a deteriorating surface is not an ideal roof or wall material to protect against the elements. To address this need, different options have been developed including the use of thicker steel products, specialty weathering steel products, and painted finishes that recreate rust aesthetics. So, what are the key differences between naturally rusting products and a painted rust finish?

Performance and Warranty

The lifespan of naturally oxidized products will be dependent on the installed environment and the presence of factors such as moisture. The rate of oxidation can also vary significantly across a singular surface based on factors such as shade and leaf litter, snowfall, and water runoff. By comparison, a painted product will have a consistent finish designed to provide a robust, consistent protective barrier across the whole surface against environmental factors. If the appropriate paint system is selected for the environment, and the roof is cleaned as required (typically a periodic rinse of debris) the color and finish of a painted surface will remain consistent across the surface for many decades.

Inconsistent corrosion

The other benefit of a painted finish is that it will carry a warranty against finish inconsistencies. Robust products such as AEP Span’s PVDF Rustic series can carry finish warranties of up to 30 years. These painted products may also carry the added benefits and warranty of ZINCALUME. ZINCALUME is a specialty metallic coating added to the steel before it is painted and provides a corrosion warranty of 25 and a half years, so this means end users can achieve the visual impact of rust but with the peace of mind, the performance of the roof or wall surface will not deteriorate.

A painted finish – AEP Span’s Burnt Rust

Material usage and Weight

Naturally rusting products typically use a thicker base metal to combat the effects of rust. Either they use a thicker base to simply extend the time it takes to corrode the metal or for specialty products such as weathering steel, it features a surface that rusts but forms a barrier preventing the corrosion of the core steel underneath. In either instance, both involve using a thicker and subsequently heavier metal compared to traditional metal roof and wall products.

Outside of the cost of purchasing more material, the thicker base metal can significantly add to the weight of the structure and may require additional building reinforcement or structural planning to ensure it can carry the weight of the additional material. Painted rusted metal roofing and siding uses the same paints and processes as regular metal roof and wall products. This means these painted products are available in the same standard thicknesses and widths as traditional metal products which offer exceptional performance relative to weight.

Design vision fulfilled with a painted rust finish

Finish and color variability

Naturally oxidized finishes will have greater variability in the finish as the visual patina occurs naturally based on a variable interaction with the broader environment. Printed rust designs will offer variability in the pattern but will be limited by the diameter of the paint roll which applies to the printed design. This means that eventually, the pattern will repeat every three to five feet. Printed designs like Aep Span’s Burnt Rust or Rustic Rawhide have been specially developed to create patterns that blend repeated sections to avoid creating a visible, inauthentic ‘wallpaper’ style effect on a surface. This underpins why specially formulated painted designs do not feature large prominent features as these will create a noticeable pattern that will repeat on a surface.

Sedona Rust swatch – note how it does not feature any prominent features to improve realism once installed

Naturally oxidized finishes can offer different shades of rust and typically this color will change and dull over time based on the age of the material and surrounding environmental conditions. For example, freshly oxidized material tends to have a bright orange glow patina, whereas long-term oxidized finishes dull to a more consistent, dark brown patina. While painted finishes do not offer the same finish evolution as a natural finish, the different shades of rust available (such as the red rust of AEP Span’s Sedona Rust v the darker brown of Natural Rust) enable designers and building owners more control in selecting the shade of rust suitable to their design vision.

The warm fresh rust glow of AEP Span’s Sedona Rust

Texture

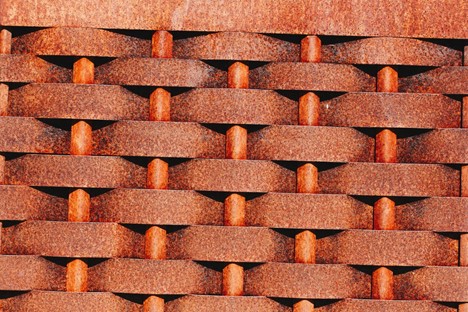

Naturally oxidized finishes are often selected for their slightly rough surface texture which can add additional appeal to an exterior roof or wall surface. This is created by the surface of the material corroding inconsistently, creating microscopic peaks and valleys on the surface.

The texture of a naturally oxidized finish

Thanks to advances in modern paint technology, this texture can be recreated and still carry all the performance attributes of a painted finish. Finishes such as Rustic Rawhide feature a paint technology that ‘crinkles’ during the curing process to create a light but defined texture. As this crinkling occurs within the confines of the closed-loop metal painting process, it still creates a consistent finish and a tight bond to the metal, enabling all the benefits of a painted finish including long warranties.

The texture of Rustic Rawhide

The added benefit of texture is that it can reduce the visible gloss and sheen of the surface when struck by sunlight as the varied texture reflects light in a more inconsistent direction. In some applications, reduced gloss and sheen can improve the way the surface interacts with the rest of the structure.

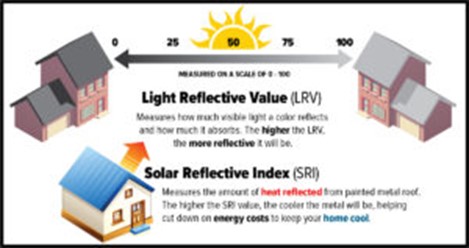

Solar Reflectivity

Unlike a traditional oxidized finish, a painted rusted finish can take advantage of all the advances in modern paint technology. This means that finishes, such as AEP Span’s rustic series, use modern ‘Cool’ pigment technology. Cool pigments are designed to better reflect the heat from the sun (infrared radiation), transferring less of the heat to the structure, reducing building cooling costs. These factors are important considerations as part of modern building programs such as LEED or Living Building Challenge.

Upkeep and Maintenance

Naturally oxidized or rusted finishes can create more maintenance headaches compared to a painted rusted finish. Particularly when new and the oxidized surface is unstable, factors such as rainwater can dissolve the rust, washing it off to surrounding areas. For some surfaces, particularly stone and concrete this rust runoff can lead to permanent, unsightly staining. Some weathered steel products may also require treatment or varnish to stabilize the rate of corrosion and prevent further structural degradation. By comparison, a painted metal surface will just need to be periodically rinsed of dirt and organic material accumulation such as leaves, directions for these simply cleans are typically provided in the products finish warranty.

Learn More

At AEP Span we specialize in the development of authentically painted metal patinas and rust finishes. To learn more about the painted metal used for metal roofing and siding, visit our learning center.

Click HERE to explore our products in greater detail!

Finally, if you need any metal product assistance, reach out via Ask AEP Span.

Did you find this article helpful?