What’s Behind the Paint?

In this multipart blog series, we will look at all there is to know about paint on metal coils. The goal is to help you gain a better understanding of why painted metal is an ideal choice for your next project and how to make the best metal selections. Read on to learn more!

We all know what “paint” is, it’s something you slather on the walls to change up the look right? But what’s behind the paint?

Paint is…

“A liquid designed for application to a surface in a thin film that cures to a solid film….or basically, a coating that protects the surface of an object. It is also used to create aesthetics and visual effects often accomplished through the various layers and treatments of paint.”

But paint is actually a culmination of several treatments when it comes to metal coils.

PAINT LAYERS

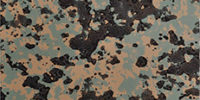

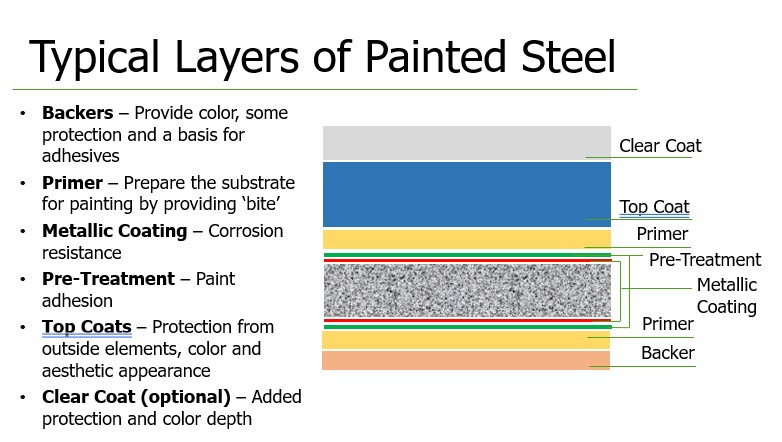

Paint is made up of several layers. The 3 types of layers are primers, backers, and topcoats, which all come together to form a complete coat of paint.

COIL COATING CHARACTERISTICS

There are several characteristics to consider when coating steel coils. Some of these are:

- Weatherability – Resistance to moisture, sunlight, temperature changes

- Flexibility – Able to be formed without cracking

- Appearance – Available in various gloss ranges

- Color – Maximum color retention, a wide variety of colors available

- Application – Applies easily on the line resulting in the desired finish

- Cure – Dries completely within the specified dwell time and temperature

The coil coating process itself is about 25 times faster than any other metal coating process! The coil metal coating process requires a coating to cure as fast as 15-30 seconds. A bake of 5-10 minutes is more common for many Industrial Coatings. Not only that, a typical coil coating paint system is about 1.4 mils (topcoat, primer, backer). That’s .0014 of an inch!!! Most other industrial coatings are in the neighborhood of 2-5 mils.

Let’s put this in perspective, a car takes about 30 minutes to prime and topcoat; a metal building (say, 50 feet x 30 feet x 20 feet; wall and roof) is painted in about 5 minutes on a coil coating line! No other coating is expected to have the usual 40+ years lifetime that coil coatings have. What is the average car paint warranty? Typically, only about 5 years or 60,000 miles.

Most metal coating processes involve a prefabricated part, whereas pre-painted metal is always post-formed. Therefore, a coil coating must be hard, damage-resistant, and flexible enough to withstand the forming operations.

In our next blog we will talk about the components that make up the paint itself, pigments, and much more!

Did you find this article helpful?